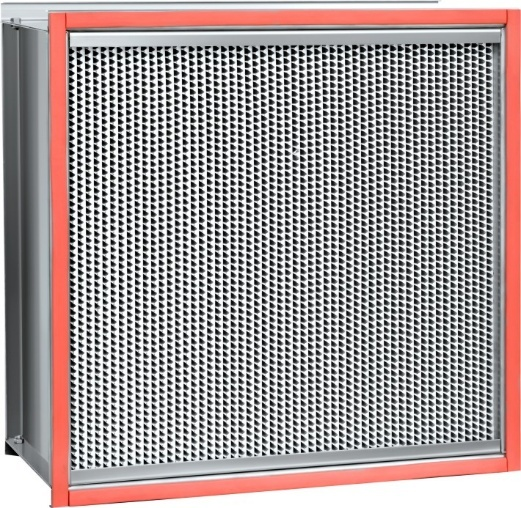

NGB High Temperature-resistant 350℃ Separator HEPA Filter

The filter material is high temperature resistant ultra-fine glass fiber filter paper, and the separator is aluminum foil corrugated sheet.

The filter material is high temperature resistant ultra-fine glass fiber

filter paper, and the separator is aluminum foil corrugated sheet. The filter

paper is fixed and sealed in the outer frame of the SS304 stainless steel plate

with special high-temperature resistant silicone or ceramic glue. The

installation sealing material is silicone rubber, PTFE or glass fiber cotton.

There are various specifications such as temperature resistance 250 ° C, 280 °

C, 350 ° C for customers to choose. Mainly used in equipment and systems

requiring high temperature air purification such as tunnel ovens and ultra-clean

ovens.

|

Frame |

Stainless steel |

|

Spacers |

Aluminum foil |

|

Filter media |

Glass fiber |

|

Gasket |

High-temp resistant silica seal strip |

|

Operation conditions |

<80%RH |

|

Model |

Dimensions(mm)(L×W×D) |

Rated airflow(m³/h) |

Nitial pressure drop(Pa) |

Final pressure drop(Pa) |

Efficiency@MPPS |

|

NGB484.484-150H14 |

484×484×150 |

600 |

220 |

450 |

99.995%≤E<99.9995% |

|

NGB610.610-150H14 |

610×610×150 |

1000 |

|||

|

NGB610.610-180H14 |

610×610×180 |

1200 |

|||

|

NGB484.484-220H14 |

484×484×220 |

1000 |

|||

|

NGB610.610-220H14 |

610×610×220 |

1500 |

|||

|

NGB610.610-292H14 |

610×610×292 |

2000 |

Product Advantages:

-

Maximum continuous operating temperature: 350°C!

-

Maximum instantaneous operating temperature: 400°C!

-

Capture efficiency: 99.97%.

-

Customizable filtration efficiencies available.

-

Suitable for ultra-clean ovens, tunnel sterilization, and other purification equipment.

-

High-temperature filter paper that does not shed fibers or decompose under high temperatures.

-

Aluminum foil spacers, silicone rubber seals, and stainless steel frames to meet high-temperature requirements.

-

Reinforced edges with stiffeners to meet strength requirements.

Product Schematic Diagram:

Related products

-

KSZHDM-03 Combined Grinding Dust Collector

Contact UsFeatures:

● Reasonable structure design facilitates dust settlement

● Convenient dust removal, automatic dust removal to ensure the continuity and efficiency of production

● Low noise and easy to use

● PLC control system control, humanized operation panel design, easy to use

● High filtration accuracy, high efficiency and long service life -

KSXH-20B Soldering Fume Extractor

Contact UsFeatures:

● light weight, easy to operate

● Adjustable flexible POM suction arm

● High-power DC brush-less motor

● Multi-level-filtration,cotton filter, HEPA filter and activated carbon filter

● Long service life, low noise, large air flow -

Medical waste incinerator

Contact UsWuxi Airali Environmental Protection Technology Co., Ltd. is a company specializing in the manufacture, sales and engineering installation of environmental pollution prevention and control equipment

-

KSZ-1.5S1/S2 Welding Fume Extractor

Contact UsFeatures:

● High efficiency custom aluminum impeller

● Self-supporting & self-positioning suction hood

● Durable flexible suction arm, high temperature resistance & flame retardant & abrasion resistance

● Easy to replace and clean filters, no frequent maintenance is required

● Imported filter material with high precision filtration

● Special designed dust cleaning device, automatic blow-back cleaning

● Siemens PLC smart control system, more intelligent and energy saving

● Integrated automatic fire extinguish system

Reviews

There are no reviews yet.