LCTW Dynamic pass box

The self-cleaning transfer window allows for the transfer of materials, utensils, and other items under Class A environmental protection. Items are self-cleaned within the window before entering areas of higher cleanliness. The self-cleaning transfer window is equipped with an ultraviolet sterilization lamp and can also be fitted with a royal oxygen sterilization system according to user requirements.

Dynamic pass box is an equipment used for transfer of goods, and could

segregate the air on both sides of the room. It is installed at the entrance to

Clean Room in order to minimize the amount of particulate contamination entering

the Clean Room.

|

Model |

Overall dimensions(L×W×D) |

Work area size(L×W) |

Work area |

Air outlet |

Noise(dB) |

Ozone concentration(ppm) |

Ultraviolet |

Power(KW) |

|

LCTW4-50.50.50 |

700×1000×550 |

500×500×500 |

A |

0.45±20% |

65 |

20-50 |

8 |

0.15 |

|

LCTW6-60.60.60 |

800×1100×650 |

600×600×600 |

15 |

0.15 |

||||

|

LCTW8-70.70.70 |

900×1200×750 |

700×700×700 |

15 |

0.15 |

Note:The specifications listed in the table are only for reference.The

products can be designed and manufactured according to URS of customers.

Product Advantages:

Flat electromagnetic interlock ensures high reliability.

The work area features an integrated arc design, leaving no dead corners and making it easy to clean.

Double-layer negative pressure design eliminates the risk of leakage.

Available in various configurations, including corner type, triple-door type, and double-layer type.

Optional Chinese/English operation interface and manual/automatic modes.

Door types: stainless steel frame with tempered glass, embedded tempered glass, or hanging tempered glass.

Wiring options: top wiring or side wiring. Additional configurations: UV lamps, ozone generators, etc., can be added upon request.

Transfer direction is adjustable, and operating parameters have a wide adjustment range, effectively preventing cross-contamination.

All components are designed to be corrosion-resistant, durable, and have a long service life.

Tempered glass doors provide internal visibility.

Equipped with proprietary self-cleaning clean transfer window patent technology.

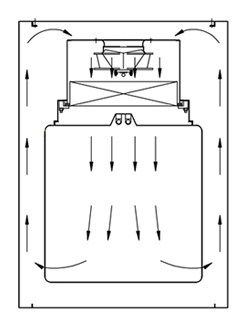

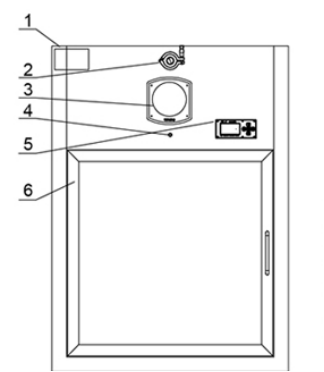

Product Schematic Diagram:

| Airflow Diagram | Structural Diagram | External View Diagram | |

|

|

1. Cabinet 2. DOP Particle Injection Port 3. Pressure Gauge 4. DOP Sampling Port 5. Control Panel 6. Double-Layer Glass Door |

|

Related products

-

Hazardous waste incineration device project

Contact UsThis project plans to build a treatment of 50,000 tons of organic substance solvents comprehensive recycling and utilization project hazardous waste incineration device, to incinerate the hazardous waste generated by the our factory and for receiving waste from other companies.

-

KSDC-8604A/A1 Centralized Dust Collector

Contact UsFeatures:

● Compact and reasonable structure design

● Convenient dust removal, fully automatic dust removal, to ensure the continuity and efficiency of production

● Dust collection, container loading and unloading is convenient, the connection with the filter funnel is sealed, no dust leakage

● Intelligent control, optional automatic inverter, remote linkage function

● PLC control system control, humanized design of operation panel, easy to use

● The imported high-quality polyester filter material is used, and the surface of the filter material is covered with a high-precision PTFE membrane, which has higher filtration accuracy and higher filtration efficiency -

Regenerative thermal incinerator (RTO)

Contact UsCoating, textile, pharmaceutical, chemical organic waste gas of low concentration, big air volume;

-

KSZHDM-03 Combined Grinding Dust Collector

Contact UsFeatures:

● Reasonable structure design facilitates dust settlement

● Convenient dust removal, automatic dust removal to ensure the continuity and efficiency of production

● Low noise and easy to use

● PLC control system control, humanized operation panel design, easy to use

● High filtration accuracy, high efficiency and long service life

Reviews

There are no reviews yet.