VMC 1166 3 Axis Vertical Machining Center

The machine is suitable for the production of communication electronics, automobile and motorcycle parts and automated parts processing.

https://www.josencnc.com/VMC-1166-CNC-Vertical-Machining-Center.html

The machine is suitable for the production of communication electronics, automobile and motorcycle parts and automated parts processing. Its bed adopts a high rigidity structure and a large number of reinforcement bars inside the casting to ensure the rigidity and stability of the whole machine. The front end of the spindle is equipped with a ring-shaped water outlet, which can effectively cool the cutting tool. The base adopts a large span structure with two 45mm roller line rails, which makes the machine have strong load capacity and high rigidity.

1.This model is suitable for communication electronics, automobile and

locomotive parts production, and automated parts processing.

2.Combined with FEM analysis, the main components of the base, column and

saddle all adopt unique high rigidity structure, which makes the internal force

structure of the whole machine more optimized and ensures the rigidity and

thermal variation stability of the whole machine.

3.Three axes linear precision rolling guide design, fast acceleration and

deceleration response, effectively improve the machining efficiency and

machining accuracy of the machine, even under heavy load is also excellent.

4.The front end of the spindle is equipped with a circular water jet to allow

effective cooling of the cutting tool, while the internal air curtain with

negative pressure extends the service life and ensures reliable use of the

spindle for long time and high-speed operation.

5.The stable base and column with lightweight motion axis components

effectively ensure the stability of the machine during high acceleration and

deceleration movements.

| ITEM | UNIT | DV-1166 | DV-1166B |

| Travel | |||

| X-axis travel | mm | 1100 | 1100 |

| Y-axis travel | mm | 620 | 620 |

| Z-axis travel | mm | 600 | 600 |

| Worktable size | |||

| Working table size (X*Y) | mm | 1200×600 | 1200×600 |

| Max.loading capacity of working table | kg | 900 | 900 |

| Table T-slot size (width * number of slots * spacing) | number | 18x5x100 | 18x5x100 |

| Spindle | |||

| Spindle speed | rpm | 10000 | 8000 |

| Spindle drive form | belt driven | belt driven | |

| Spindle power | kW | BT40:11/15 | BT50:15/18.5 |

| Spindle bore specification | BT40 | BT50 | |

| Distance from spindle to table surface | mm | BT40:125-725 | BT50:145-745 |

| Spindle feed | |||

| Rapid feed rate(X,Y,Z) | m/min | 36/36/36 | 36/36/36 |

| Cutting feed rate | mm/min | 10000 | 10000 |

| Tool magazine | |||

| Tool magazine capacity | cutter arm type 24 | cutter arm type 24 | |

| Tool diameter/adjacent tool space | mm | BT40:Φ80/Φ150 | BT50:Φ110/Φ200 |

| Max. Tool length | mm | 300 | 300 |

| Max. Tool weight | kg | BT40:8 | BT50:15 |

| Accuracy | |||

| Positioning accuracy | mm | ±0.005 | ±0.005 |

| Reproduction accuracy | mm | ±0.003 | ±0.003 |

| Others | |||

| Controller | 0i-MF/M80 | 0i-MF/M80 | |

| Air pressure demand | kg/cm2 | 6 | 6 |

| Power demand | kVA | 30 | 30 |

| Machine weight | T | 6.5 | 6.5 |

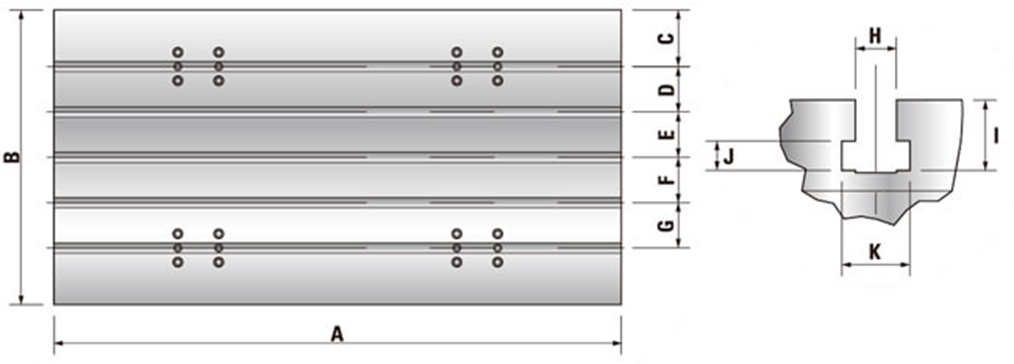

| Model | A | B | C | D | E | F | G | H | I | J | K | T-slot number |

| DV-1166 | 1200 | 600 | 100 | 100 | 100 | 100 | 100 | 18 | 31 | 13 | 30 | 5 |

| DV-1166B | 1200 | 600 | 100 | 100 | 100 | 100 | 100 | 18 | 31 | 13 | 30 | 5 |

Related products

-

Used NSC Schlumberger FM7N Spinning Machine

Contact UsThe company was established in Zhangjiagang, Jiangsu, China in 2005 .Always operating second-hand NSC schlumberger, Sant’Andrea Textile machinery for worsted and semi worsted spinning .

-

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

-

Dry type transformer

Contact UsSafe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free

-

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

Reviews

There are no reviews yet.