JC-2S96E2 Side Open Two Panel Door System

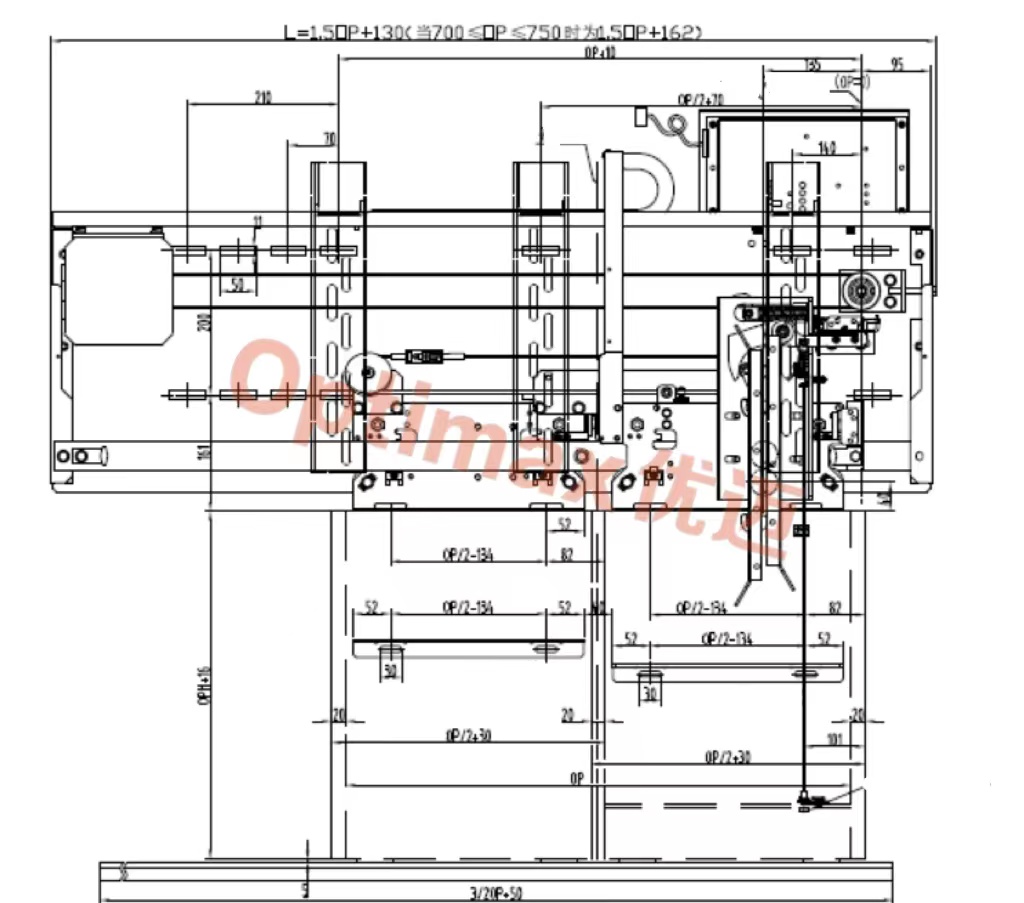

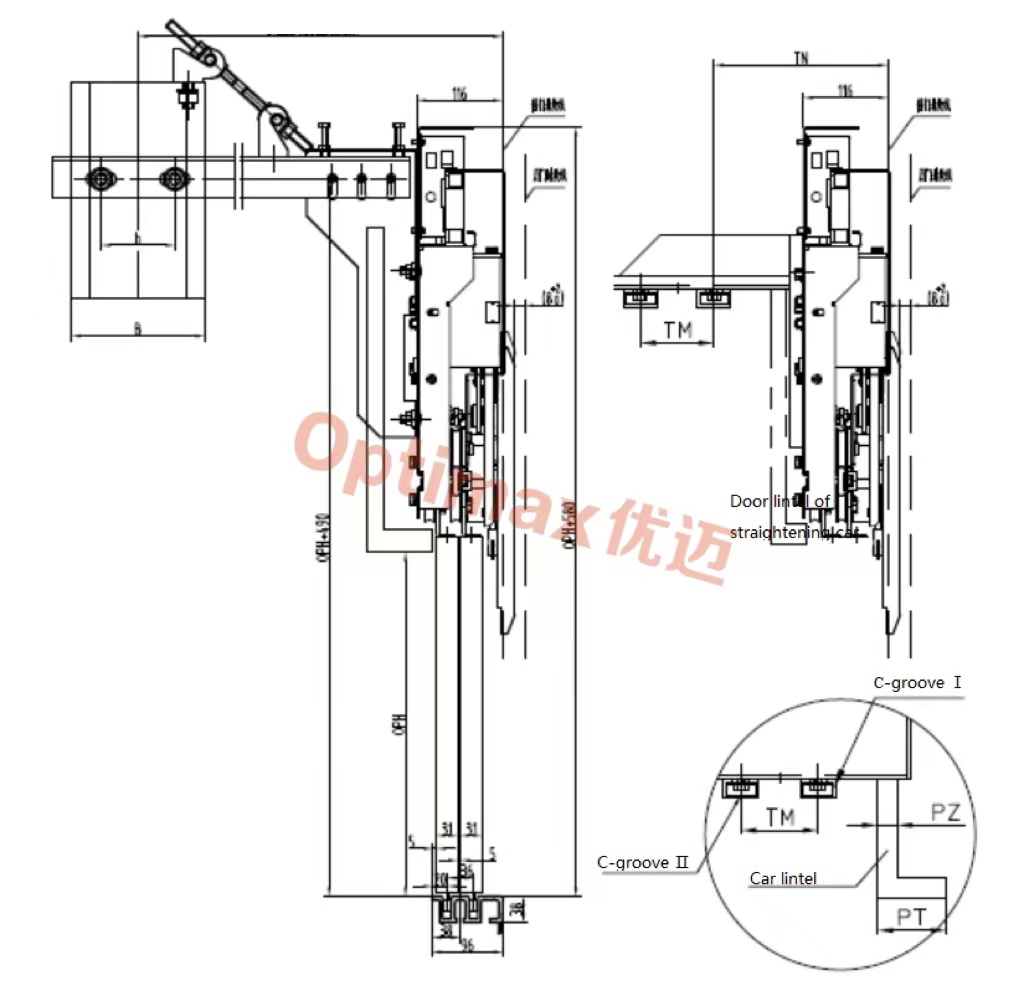

JC-2S96E2 Side Open Two Panel Door System features a 96 mm sill and 116 mm thickness, supports steel door panels, operates up to 2 m/s, and fits openings from 700–1800 mm wide and 2000–3000 mm high.

https://www.xizi-ec.com/JC-2S96E2-Side-Open-two-panel-door-system-with-96-sill.html

Opening type:Side Open Two Panel

Sill Width:96mm

Thickness:116mm

Speed: Maximum 2m/s

Match The Door Panel Material: Steel Door

OP(mm):700-1800

OPH(mm):2000-3000

This product is a door driving system subject to permanent-magnetic synchronous motor driving and stepless speed regulation VF control. It is easy for installation and debugging and reliable in operation. Its most important advantage is that the structure is very compact, which brings high use ratio of hoistway. This product is widely used in passenger elevator and freight elevator.

Data Sheet Unit:mm

|

OP(Clear Opening Width) |

700 |

750 |

800 |

850 |

900 |

950 |

1000 |

1050 |

1100 |

1150 |

1200 |

1250 |

1300 |

1350 |

1400 |

1450 |

1500 |

1550 |

1600 |

1650 |

1700 |

1750 |

1800 |

|

L |

1206 |

1281 |

1324 |

1399 |

1474 |

1549 |

1624 |

1699 |

1774 |

1849 |

1924 |

1999 |

2074 |

2149 |

2224 |

2299 |

2374 |

2449 |

2524 |

2599 |

2674 |

2749 |

2824 |

|

C |

As per Request |

||||||||||||||||||||||

|

K1 |

Default Value:100,or As per Request |

||||||||||||||||||||||

|

SW |

Default Value:180,or As per Request |

||||||||||||||||||||||

|

HS |

Default Value:OPH+490 |

||||||||||||||||||||||

|

Door Vane Structure |

Integrated Door Lock Synchronous Door Cam, Effective length of door cam 320mm |

||||||||||||||||||||||

|

Installation Mode |

Straight Beam Installation Mode/Car Top Installation Mode |

||||||||||||||||||||||

Related products

-

20KVA/16KW Diesel Generator With Cummins Engine

Contact UsOur 16KW 20KVA diesel generator with Cummins engine is ideal for reliable power solutions.

-

High-efficiency activated carbon attachment device

Contact UsHigh-efficiency activated carbon attachment device can quickly absorb pollutants in exhaust gas. The exhaust gas containing pollutants is powered by a fan and enters the activated carbon adsorber under negative pressure.

-

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export. -

Dry type transformer

Contact UsSafe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free

Reviews

There are no reviews yet.