Gate Valve Gear Operated With Extended Stem API600

Gate valve is one of the most common on-off valves. It uses the up and down movement of the gate plate to connect (fully open) and cut off (fully closed) the fluid medium in the pipeline.

I. Purpose and Characteristics

Gate valve is one of the most common on-off valves. It uses the up and down

movement of the gate plate to connect (fully open) and cut off (fully closed)

the fluid medium in the pipeline. It is widely applicable to pipelines of

various systems in petroleum, chemical, hydraulic, and thermal power stations to

cut off or connect pipelines.

1. Low fluid resistance. The sealing surface is less scoured and eroded by

the medium (the gate plate has a high opening height).

2. Opens powerfully. Has good sealing performance. The medium flow direction

is not restricted, without disturbing flow or reducing pressure.

3. Simple in shape. Good in manufacturing technology and has a wide range of

applications.

II. Product Implementation Standards

American standard gate valves comply with API600/API6D standards.

Casting gate valves comply with ISO10434.

American standard valves comply with ASME B16.34 standards.

Structural length complies with ASME B16.10 standards.

Flange dimensions comply with ASME B16.5 standards.

Butt welding complies with ASME B16.25 standards.

Testing and inspection comply with API598/API6D standards.

III. Design Description

Full bore design.

Rising stem with yoke.

Bolted bonnet.

Resilient wedge, with guide.

Solid or split wedge.

Forged T-stem.

Non-rising handwheel.

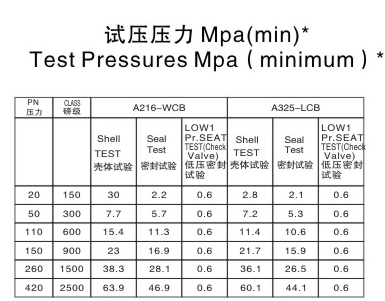

Ⅳ. Test Pressure Mpa

Applicable Medium and Applicable Temperature.

|

Housing material |

Applicable media |

Applicable temperature (℃) |

|

Carbon steel (type C) |

water, steam, oil |

≤425 |

|

Chromium nickel titanium steel (P type) |

Nitric acid |

≤200 |

|

Chromium Nickel Molybdenum Titanium Steel (R Type) |

Acetic acid |

≤200 |

|

Chromium molybdenum steel (L type) |

water, steam, oil |

≤550 |

Material of each component.

|

No |

Part name |

Materia |

|

1 |

Body |

A216 WCB |

|

2 |

Bonne |

A216 WCB |

|

3 |

Wedge |

A216 WCB+Cr13 |

|

4 |

Stem |

A182 F6a |

|

5 |

Seatring |

A105+CR13 |

|

6 |

Stem backsea |

A276420 |

|

7 |

Bonnet gasket |

SS304+Graiphite |

|

8 |

Bonnet stud |

4193 B⁷ |

|

9 |

Bonnet stud nut |

A1942H |

|

10 |

Packing |

(Gralphite) |

|

11 |

Gland |

A276420 |

|

12 |

Gland flange |

A216 WCB |

|

13 |

Eyebolt pin |

(Carbon steel) |

|

14 |

Eyebolt |

A193 B7 |

|

15 |

Eyebolt nu |

A1942H |

|

16 |

Grease fitting |

(Copper alloy) |

|

17 |

Yoke sleeve |

A439 D2 |

|

18 |

Yoke slt ve jam nut |

ANSI 1025 |

|

19 |

Handwheel |

ASTM A395 |

|

20 |

Handwheel nut |

ANSI 1025 |

Related products

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

Capacity 1258ML Hot Filling Suitable For Krones Machine

Contact UsBottle Volume: 1258ml

Bottle Type: hot-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export. -

Water-cooled cabinet

Contact UsThe water-cooled cabinet condenser uses a water-cooled condenser, and the evaporator directly cools the air.

-

Dry type transformer

Contact UsSafe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free

Reviews

There are no reviews yet.