C2000 Hastelloy Alloy

Delivery: within 10-15 days or considering the quantity

Transport: By bulk or Containers;

Supply ability: 3000 metric tons/ month:

Payment terms L/C, T/T:

It can pack by container or bulk vessel

Standard export seaworthy packageit use steel belt with bundle according product’s size

We can make it as your requirement.

|

Product Name |

C2000Hastelloy Alloy |

|

Grade |

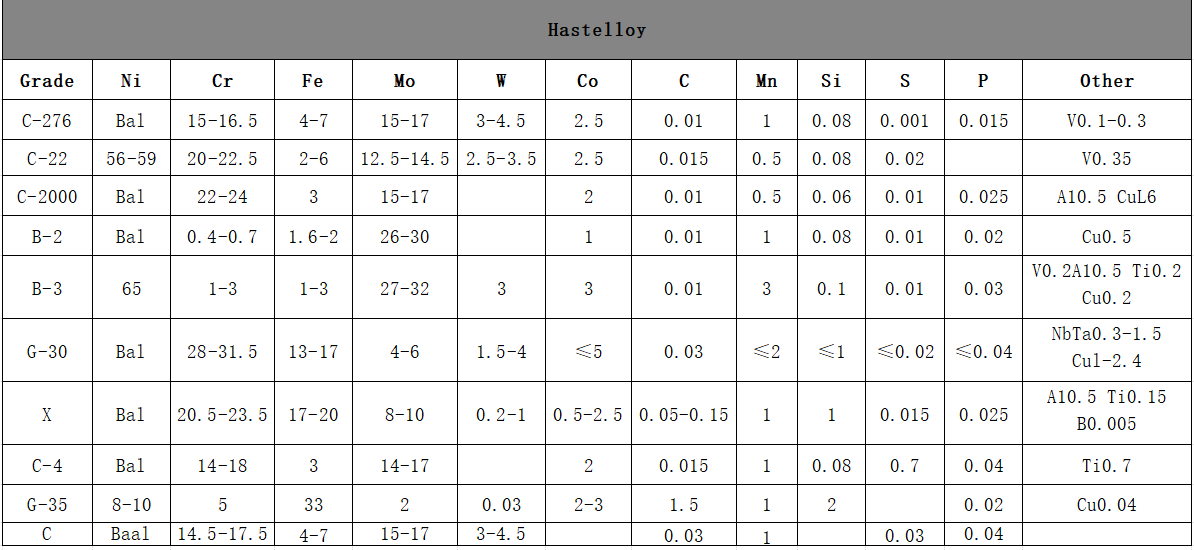

Hastelloy:hastelloyB3/B2/X/C/C22/C276/G-30Inconel:inconel600/625/718/725/617, Incoloy:incoloy800/800h/825/925,Monel:monel400/k500/404, Nickel:nickel200/201, Nitronic:Nitronic50/60, Alloy:Alloy20/28/330/31/33/75,4J36/1J50/1J79/4J29/4J42,/3J53/725Nimonic:nimonic80/80a/90/75,ETC. |

|

Techinique |

Cold Rolled or Hot Rolled |

|

Cold Rolled C2000 Hastelloy Alloy Coil/plate |

Coil Thickness: 0.3mm- 3.0mm, Width: 1000mm – 2000mm. Sheet Thickness:0.3mm- 3.0mm Width&Length:as customer requirement. |

|

Hot Rolled C2000 Hastelloy Alloy coil/plate |

Coil Thickness: 3mm- 16mm, Width: 1000mm – 2000mm. Plate Thickness:3mm- 100mm Width&Length:as customer requirement. |

|

C2000 Hastelloy Alloy seamless pipe |

Outside diameter: 4.0 – 1219mm, Thickness: 0.5 -100mm,Length: 24000mm |

|

C2000 Hastelloy Alloy welded pipe |

Outside diameter: 6.0 – 2800mm, Thickness: 0.3 -45mm,Length: 18000mm |

|

C2000 Hastelloy AlloyStrip |

Thickness:0.3mm- 16.0mm Width&Length:as customer requirement. |

|

Package |

1.cases packedinwooden cases 2.paper packaging 3.plastic packing 4.foam packaging |

|

Usage |

1.Pulp and manufacturing industries, such as boiling and bleachingcontainers 2.Scrubbertowers in FGDsystems,re-heaters,moisturefans,etc. 3.Reactors for acetic acid and cid products 4.Production and processing of impure phosphoric acid |

|

Deliverytime |

Depends on quantity |

|

Payment |

30%T/TAdvance+70%Balance beforeshipment |

|

Place ofOrigin |

China |

Productdetails

Product Description:

Hasteloy G30 Plate is a specalized mickelchromium ron- molvbdenum allov plate. designed explicitly for excelence mn high-temperature. high-chloride. and oxidizingenvironments making it ideal for niche but critical industries where failure could have severe consequences. Its composition. featuring 309 chromium. 5%molvbdenum.20% iron and low carbon, delivers strong resistance to oxidizing acids (hitric acid. chromic acid) and chlride-induced stress corrosion cracking (SCC) amajor concern in high-chloride settings.

This plate is commonly used in the nuclear imdustry,where it is fabricated into colant svstem presure vessels, spent fuel procesing eoioment linars. and reactor corecomoonent housings that handle radoactive tluds at iugh temperatres, n the chemucal mndusty it is used for ntuc acid producton reactor wals and mtrate-baseuchemical storage tank lners.as it withstands the corrosive eects of oxidlzing acids even under prolonged exposure. lt also finds applcaton im thermal processmngiabricated into heat exchanger shells and furnace liners that operate at temperatures up to 1204°0outperforming many allovs in high-temperature oxidizing conditions

Mechanically, Hastelloy G30 Plate provides stable strchural performance, with a tensle strength ofroughly 730 MPa and a yield strength of325 MPa, ensuing durabilityfor lone-term use. Cuting is feasible with plasma or laer tools. thoueh controled cuting parameters are necesarv to avoid overheatine and maintain corosion resistanceWelding involves GTAW with Hastelloy G30 filer metal. and post-weld heat treatment (typically annealing) is ofen reuired to optimize corosion resistance and relievewelding streses. For prjects operating in high-temperature, high-choride, or oxidizing environments, Hasteoy G30 Plate is a dependable, imdustry-proven choic.

Products Processing:

Hastelloy alloy material usually needs to be processed due to different applying field. OEM and ODM process is available in Yuanfataifu International Trading Co., Ltd.

We could accept post-processing requirements including cutting, bending, drilling and etc. Our expert production line and experienced worker will ensure the prime quality of all our processing work.

Related products

-

C17200 Copper Rod

Contact Us● Delivery: within 10-15 days or considering the quantity

● Transport: By bulk or Containers;

● Supply ability: 3000 metric tons/ month; -

316L Stainless Steel Plate

Contact Us316L stainless steel has a lower proportion of carbon in its composition. To qualify as 316L stainless steel, the amount of carbon cannot exceed 0.03%.

-

TP1 Copper Rod

Contact Us● Delivery: within 10-15 days or considering the quantity

● Transport: By bulk or Containers;

● Supply ability: 3000 metric tons/ month; -

304 Stainless Steel Pipe

Contact Us304 stainless steel pipe is the most common type of steel pipe across the globe for a number of its characteristics. 304 stainless steel is primarily composed of iron, chromium and nickel. This combination gives rise to outstanding oxidation resistance and corrosion resistance. 304 stainless steel is a versatile stainless steel material with better anti-rust properties than 200 series stainless steel materials. It also outperforms them in high temperature resistance. 304 stainless steel pipe features a smooth surface, high plasticity, toughness and mechanical strength, and is very resistant to corrosion by acids, alkaline gases, solutions and other media. 304 stainless steel pipes are widely used in food processing equipment, building materials, automobile parts and other fields for its versatility and relatively low cost.

Reviews

There are no reviews yet.