3G Intelligent Fin Machine

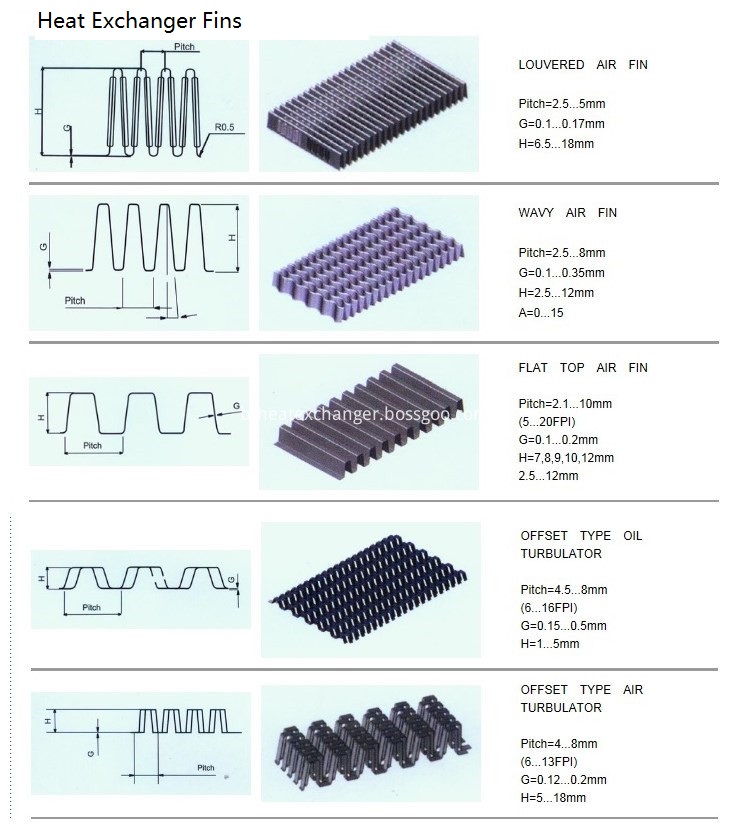

The Fin Machine is a device that directly processes the foil into various types of heat transfer fins. On the basis of the first and second generation fin machine, the third generation 3G fin machine mainly consists of 5 parts: automatic feeder, oiling device, Host machine stamping, servo control fin cutting machine and independent electrical control box. The full set of 3G automatic fin production line adopts PLC intelligent automatic control, which has the functions of automatic feeding, automatic fin forming, automatic fin cutting and electrical adjustment of mold installation. When producing different height fins with the same mold (suitable for the same fin pitch and different heights), the data can be set on the display screen for quick positioning and easy operation which greatly saves the time of debugging molds.

Core Components: Plc, Motor

Core Selling Point: Easy To Operate

Applicable Industry: Manufacturing Plant

Place Of Origin: China

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Packaging: Pallet/Case

Productivity: 300 Sets/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 300 Sets/Month

Certificate: CE

HS Code: 847480

Port: Shanghai,Ningbo

Payment Type: T/T

Incoterm: FOB,CFR,CIF,EXW

Packaging & Delivery

-

Selling Units:Set/Sets

-

Package Type:Pallet/Case

-

The Fin Machine is a device that directly processes the foil into various types of heat transfer fins. On the basis of the first and second generation fin machine, the third generation 3G fin machine mainly consists of 5 parts: automatic feeder, oiling device, Host machine stamping, servo control fin cutting machine and independent electrical control box. The full set of 3G automatic fin production line adopts PLC intelligent automatic control, which has the functions of automatic feeding, automatic fin forming, automatic fin cutting and electrical adjustment of mold installation. When producing different height fins with the same mold (suitable for the same fin pitch and different heights), the data can be set on the display screen for quick positioning and easy operation which greatly saves the time of debugging molds.

-

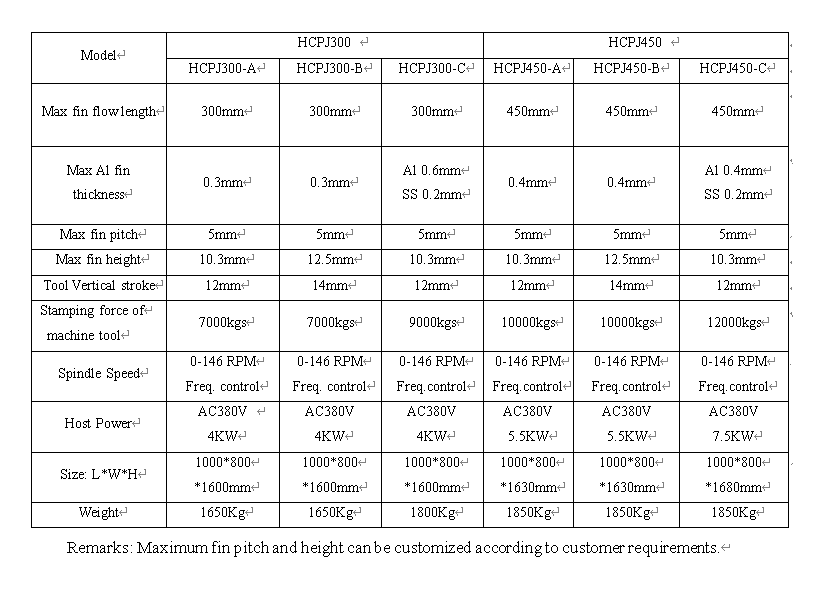

Fin Forming Machine- Main technical parameters and specifications

-

Related products

-

12Kg Medium Torque Brushless Electric screwdriver Trigger start type

Contact UsBrushless DC voltage automatic medium torque electric screwdriver series

Model: GW-B6212LF

Torque: 2~12Kgf.cm

Free Speed: HI 2000 / LO 1500 r.p.m -

OPTIMIZING CROSS CUT SAW MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

PP PE LDPE HDPE Film Recycled Plastic Washing Machine Recycling Production Line For Sale

Contact UsThe recycling washing line is mainly used to recycle all kinds of plastics, such as film, agricultural film, greenhouse film, woven bags and etc. it can also recycle waste plastic bottles such as HDPE, LDPE, PP, etc. Our output ranges from 300 kg to 2000 kg per hour. Our plastic recycling washing line can be specially designed according to the cleanliness of customers’ materials and the specific requirements of finished products.

-

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export.

Reviews

There are no reviews yet.