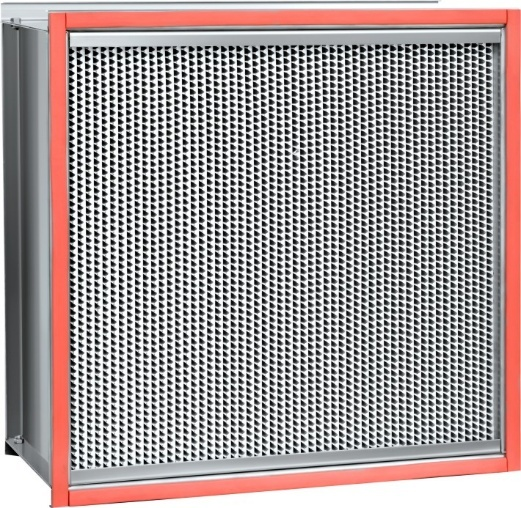

NGB High Temperature-resistant 350℃ Separator HEPA Filter

The filter material is high temperature resistant ultra-fine glass fiber filter paper, and the separator is aluminum foil corrugated sheet.

The filter material is high temperature resistant ultra-fine glass fiber

filter paper, and the separator is aluminum foil corrugated sheet. The filter

paper is fixed and sealed in the outer frame of the SS304 stainless steel plate

with special high-temperature resistant silicone or ceramic glue. The

installation sealing material is silicone rubber, PTFE or glass fiber cotton.

There are various specifications such as temperature resistance 250 ° C, 280 °

C, 350 ° C for customers to choose. Mainly used in equipment and systems

requiring high temperature air purification such as tunnel ovens and ultra-clean

ovens.

|

Frame |

Stainless steel |

|

Spacers |

Aluminum foil |

|

Filter media |

Glass fiber |

|

Gasket |

High-temp resistant silica seal strip |

|

Operation conditions |

<80%RH |

|

Model |

Dimensions(mm)(L×W×D) |

Rated airflow(m³/h) |

Nitial pressure drop(Pa) |

Final pressure drop(Pa) |

Efficiency@MPPS |

|

NGB484.484-150H14 |

484×484×150 |

600 |

220 |

450 |

99.995%≤E<99.9995% |

|

NGB610.610-150H14 |

610×610×150 |

1000 |

|||

|

NGB610.610-180H14 |

610×610×180 |

1200 |

|||

|

NGB484.484-220H14 |

484×484×220 |

1000 |

|||

|

NGB610.610-220H14 |

610×610×220 |

1500 |

|||

|

NGB610.610-292H14 |

610×610×292 |

2000 |

Product Advantages:

-

Maximum continuous operating temperature: 350°C!

-

Maximum instantaneous operating temperature: 400°C!

-

Capture efficiency: 99.97%.

-

Customizable filtration efficiencies available.

-

Suitable for ultra-clean ovens, tunnel sterilization, and other purification equipment.

-

High-temperature filter paper that does not shed fibers or decompose under high temperatures.

-

Aluminum foil spacers, silicone rubber seals, and stainless steel frames to meet high-temperature requirements.

-

Reinforced edges with stiffeners to meet strength requirements.

Product Schematic Diagram:

Related products

-

NZ-03 Nano-polyester for Drilling Fluid

Contact UsNZ-03 is a multi-polymer composed of alkane sulfonate, alkyl ester, crosslinking agent. It forms nano-solid sealing material through special technology. The special functional groups on the molecular chain has strong adsorption ability, and strong adhesion properties. NZ-03 reduces pore-pressure transmission by sealing pore throats and micro-fractures due to reasonable size distribution of NZ-03 in muds. It can be used in various water-base drilling fluids. Its recommend dosage is 1.0 – 3.0% (v/v).

-

30 tons/day liquid waste +10 tons/day solid waste hazardous waste incineration device

Contact UsThis project intends to build a 30 tons/day liquid waste +10 tons/day solid waste hazardous waste incineration device for Jining Wansheng Environmental Protection Materials Co., LTD., which is used for incineration and treatment of hazardous waste produced by the factory.

-

Annual output of 120,000 tons of DMF, 20,000 tons of NMF project – waste liquid and waste gas incineration treatment system

Contact UsThis project plans to build a set of waste liquid and waste gas direct-fired incinerator. Including but not limited to construction drawing design, waste gas feeding system, waste liquid feeding system, combustion assistance and feeding system, incineration system, waste heat recovery system, denitration system, smoke exhaust system, auxiliary system, electronic control instrument system, etc.

-

KSXH-20B Soldering Fume Extractor

Contact UsFeatures:

● light weight, easy to operate

● Adjustable flexible POM suction arm

● High-power DC brush-less motor

● Multi-level-filtration,cotton filter, HEPA filter and activated carbon filter

● Long service life, low noise, large air flow

Reviews

There are no reviews yet.