Oil-injected screw compressor Single stage SLV15

This is a small double-stage dry oil-free screw compressor, available in three models: 37kW, 45kW, and 55kW. Volume flow FAD:5.2-9.4m³/min,Discharge pressure:7-10 bar,Cooling:

SLV7.5-132

Single-stage oil-injection screw compressor

● Innovative airend design

Precisely manufactured airend, patented rotor profile, high standard parts.

● Systematic energy saving

Airend and motor 1:1 direct driven, reduce transmission loss and failure risk. – Oil-cooled PM synchronous motor, low temperature rise protecting the PM parts, stable and efficient toque output, reliable operation and longer service life.

● Advanced environmental protection and maintenance concepts

Nice appearance and compact construction, using multiple noise control technologies, low noise, super purification, small footprint, easy to maintain.

● Dedicated high efficiency frequency converter

The special high performance frequency converter can achieve low speed and high torque output, with excellent dynamic characteristics. – Wide range of voltage input, wide range of speed regulation, constant output, higher control precision. Large allowance derating design, meet the needs of different working conditions.

● Oil cooled PM synchronous motor

Use high quality PM parts with high temperature resistance of 180℃. – No excitation current inside the rotor, significantly improve the efficiency. – Small starting current to reduce the impact on the power grid. – Good force and energy performance, approximately constant efficiency and power factor.

Intelligent HMI control system

● Multiple languages

● Multiple protection functions

● Variety of input and output interface for writing and setting Standardized communication interface for group synergy

● Special module and protocol meet the communication and connection requirements to the upper computer

● All kinds of protection more comprehensive, powerful, timed start and stop functions etc., meet a variety of possible application requirements

● Intelligent iot function

● UL and CE certified

Lifetime Service and Technical Support

A completed set of solutions developed by SMEATON well manage the entire life of compressor, to achieve the goal of the minimum maintenance cost and the best performance.

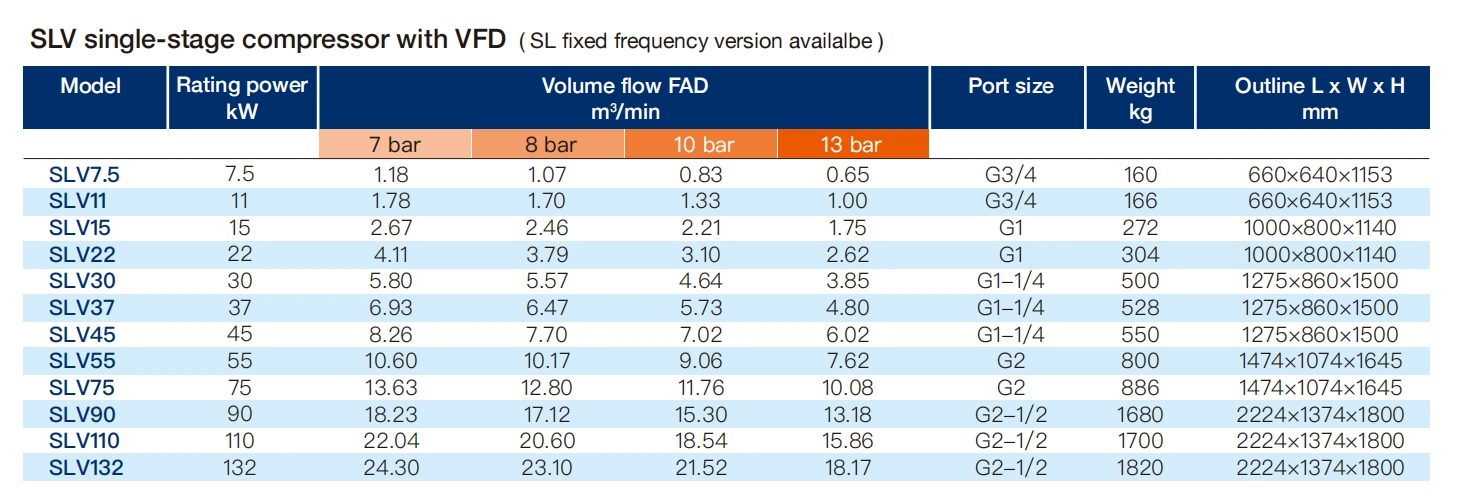

SLV single-stage compressor with VFD ( SL fixed frequency version availalbe )

SLV single-stage compressor with VFD ( SL fixed frequency version availalbe )

Related products

-

Used NSC Schlumberger GN6 Gilling Machine

Contact UsYear: 1986

Spinning production line

Mixed belt: GN6 solid ball forming machine barrel

One needle: GN6 cylinder diameter 700 * 1000mm, 1 head and 1 cylinder, self leveling

Two needles: GN6 cylinder diameter 700 * 1000mm, one head and one cylinder

Three needles: GN6 cylinder diameter 600 * 1000mm, 2 heads and 2 cylinders

According to your requirements, we can transform it into a size suitable for your production needs! -

Used NSC Schlumberger FM7N Spinning Machine

Contact UsThe company was established in Zhangjiagang, Jiangsu, China in 2005 .Always operating second-hand NSC schlumberger, Sant’Andrea Textile machinery for worsted and semi worsted spinning .

-

20KVA/16KW Diesel Generator With Cummins Engine

Contact UsOur 16KW 20KVA diesel generator with Cummins engine is ideal for reliable power solutions.

-

Capacity 1258ML Hot Filling Suitable For Krones Machine

Contact UsBottle Volume: 1258ml

Bottle Type: hot-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export.

Reviews

There are no reviews yet.