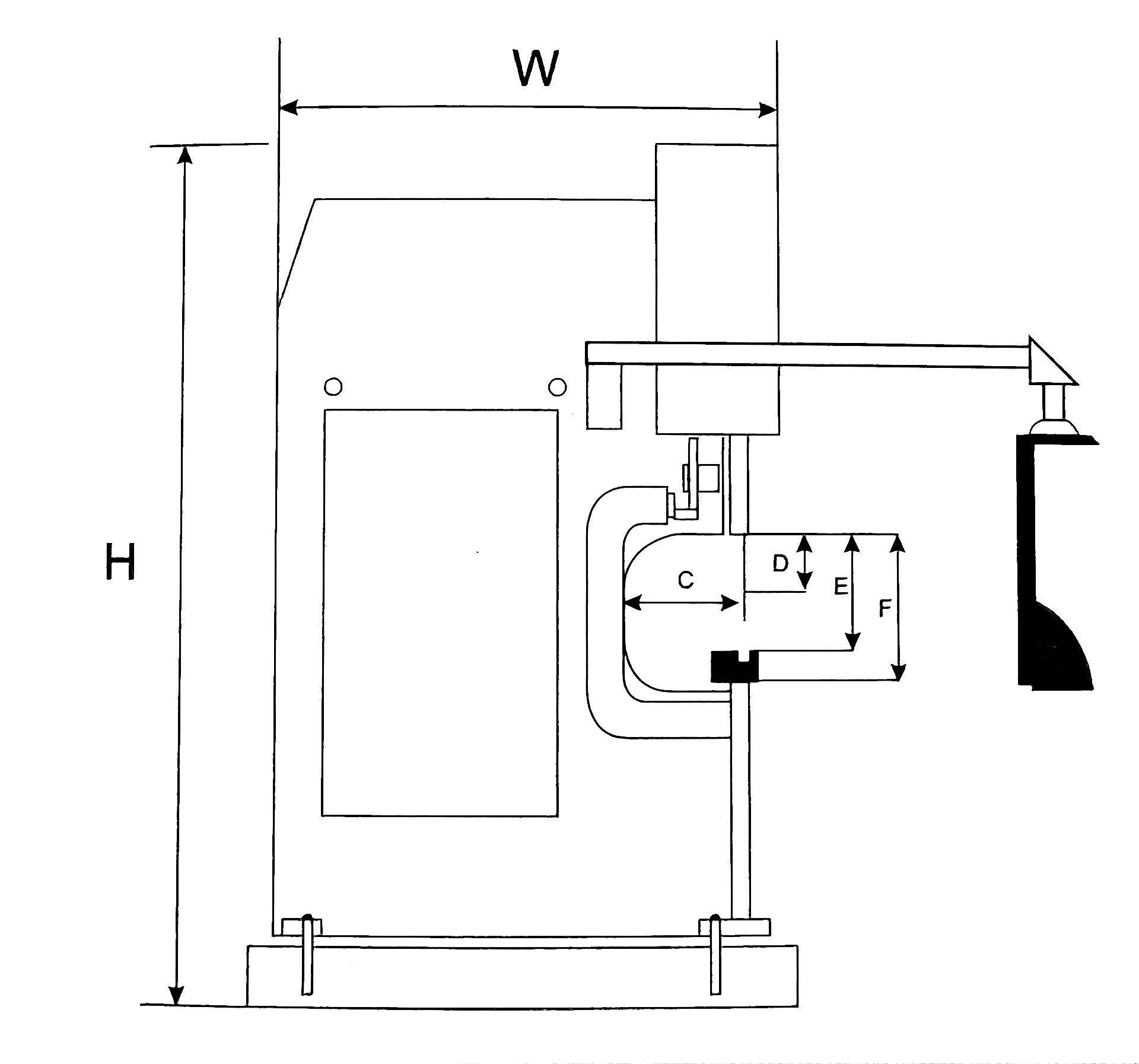

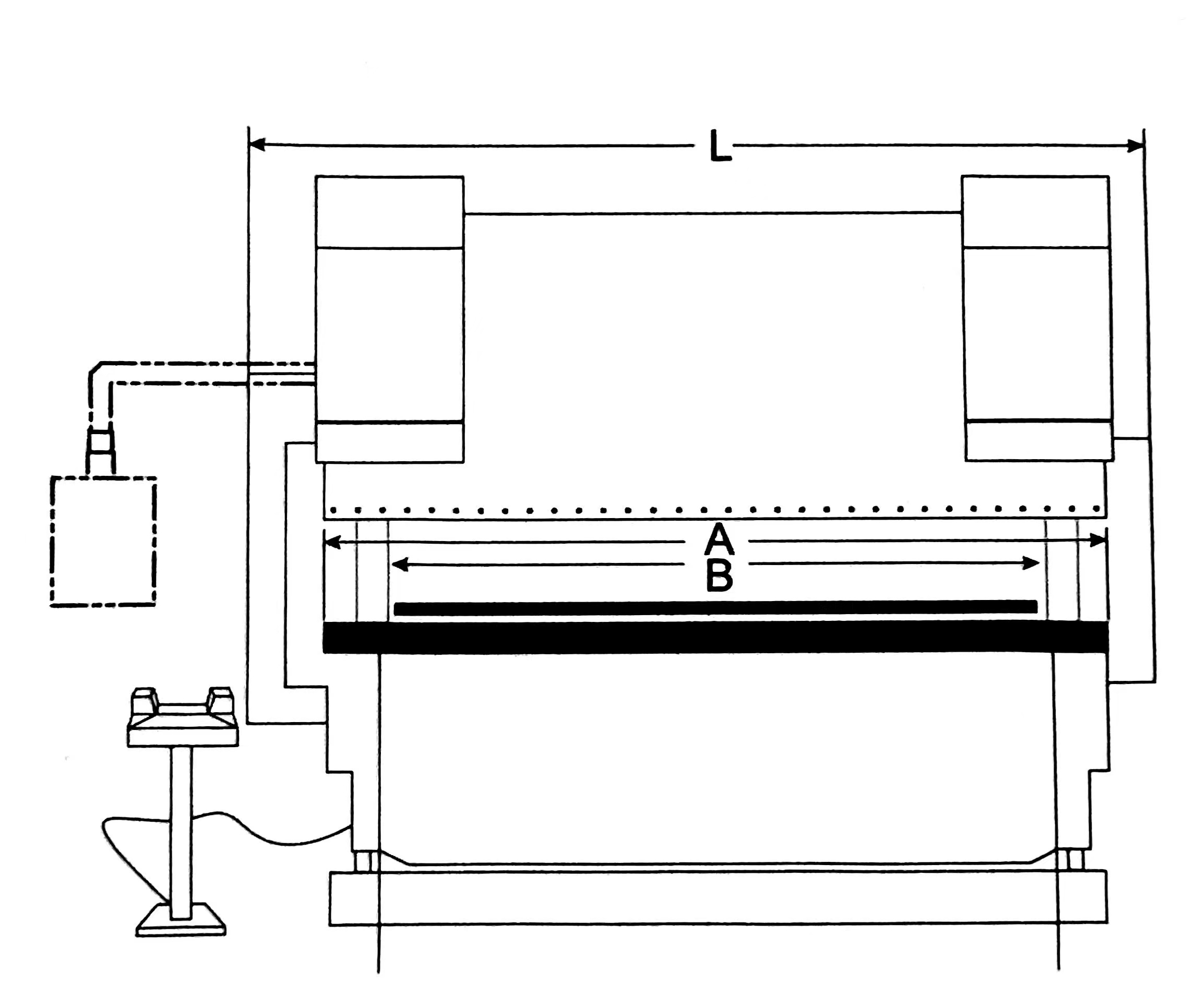

Electro-hydraulic Synchronized CNC Press Brake 220T4100 DA53T

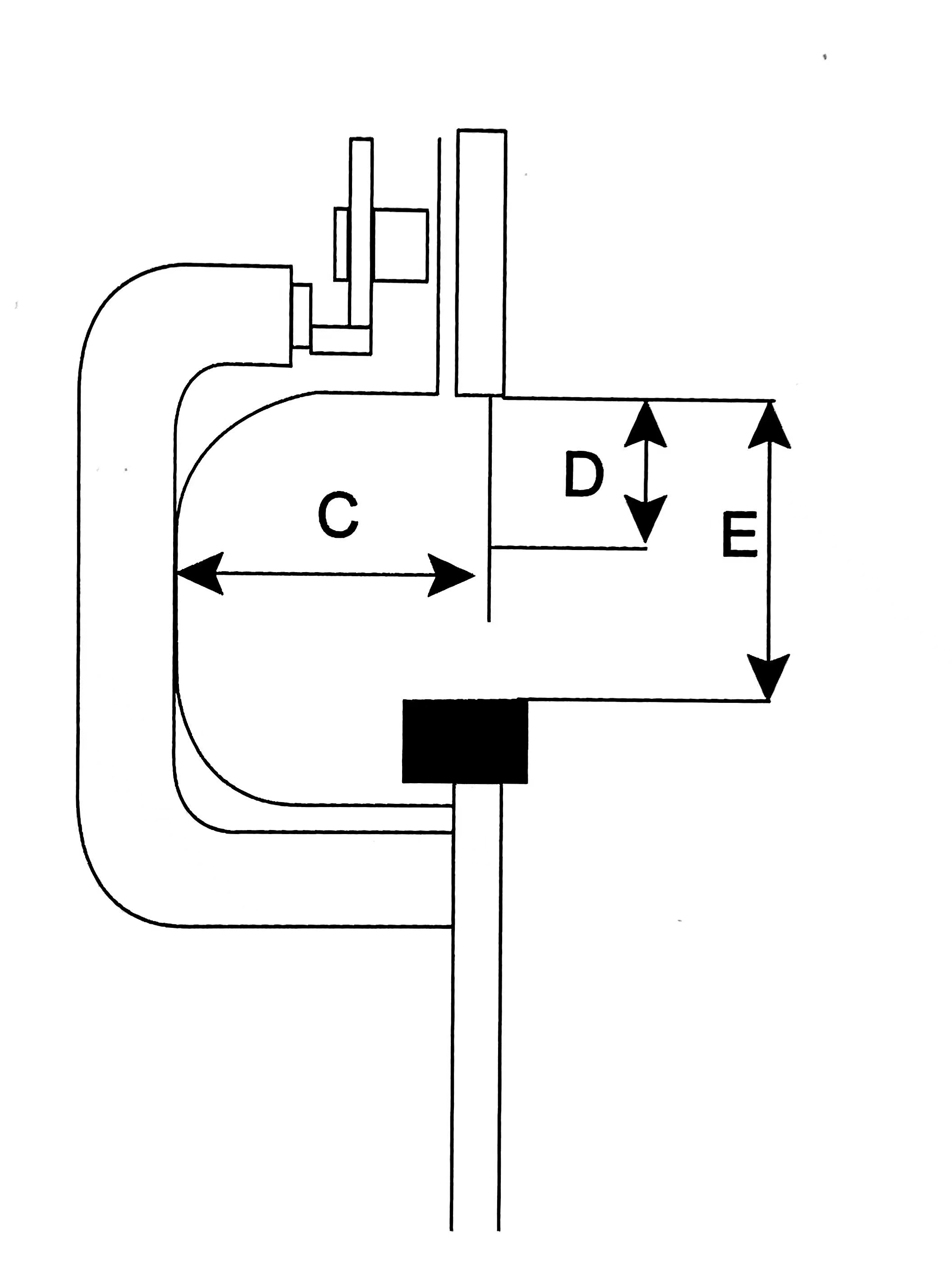

CNC sheetmetal press brake with streamlined design,high speed,high precision,high rigidity;Electro hydraulic servo system,full loop controlling the synchronization of the upper slider

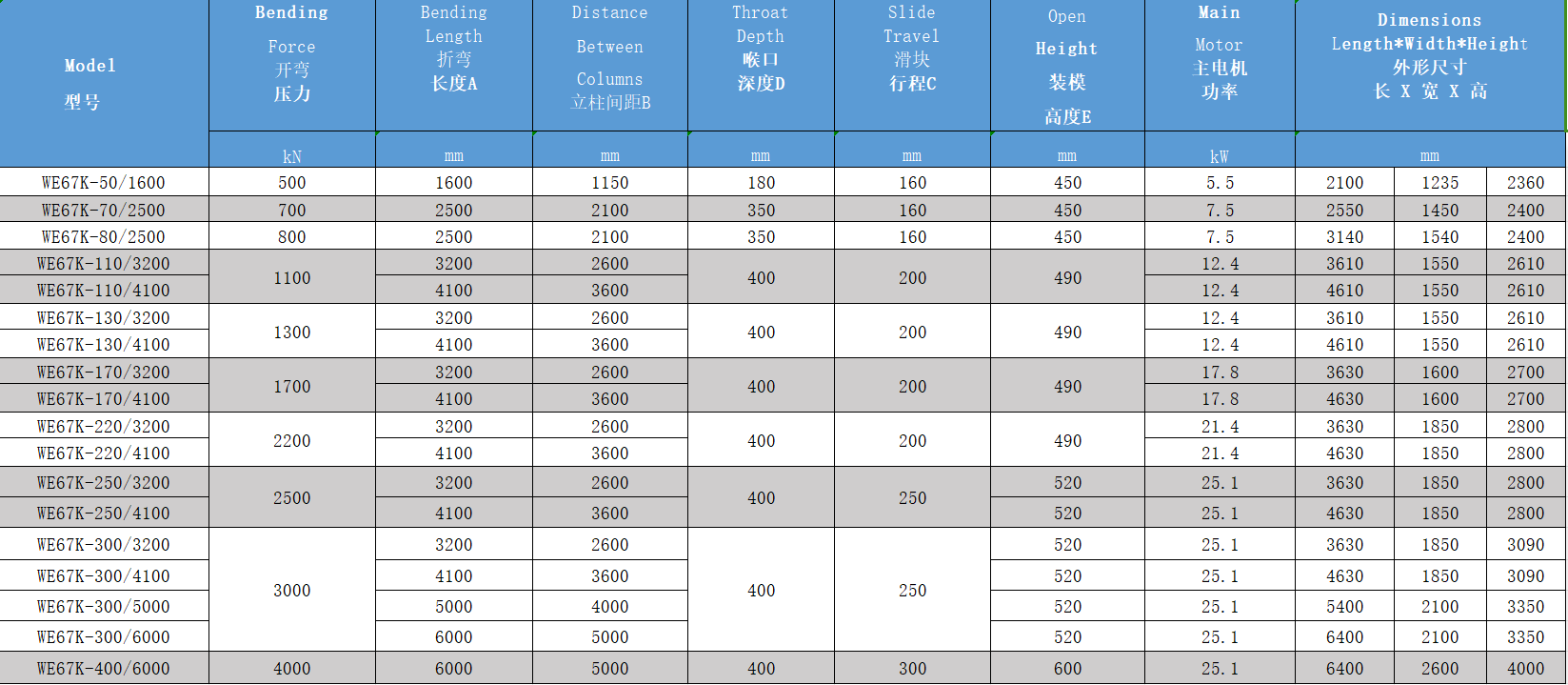

Techical Parameter

SVP Control Technology

The oil pump motor uses a servo motor to replace the ordinary motor,realise the real-time control of the motor speed, reduce the useless work of the oil pump、

and realise the energy-saving、efficient and stable characteristics of the bending machine.

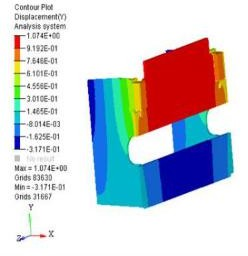

Risid Frame

Adopt all steel welding frame and assembly workbench structure, with high precision and good rigidity;UGANSYS-CAD 3D finite element analysis and optimization design

are adopted for the main components to ensure the over- all stability of the rack.

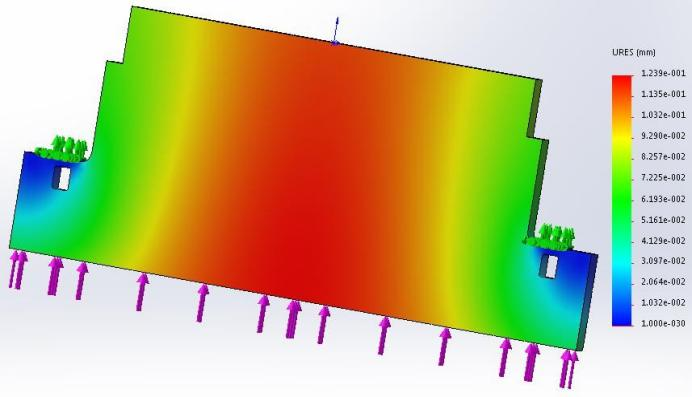

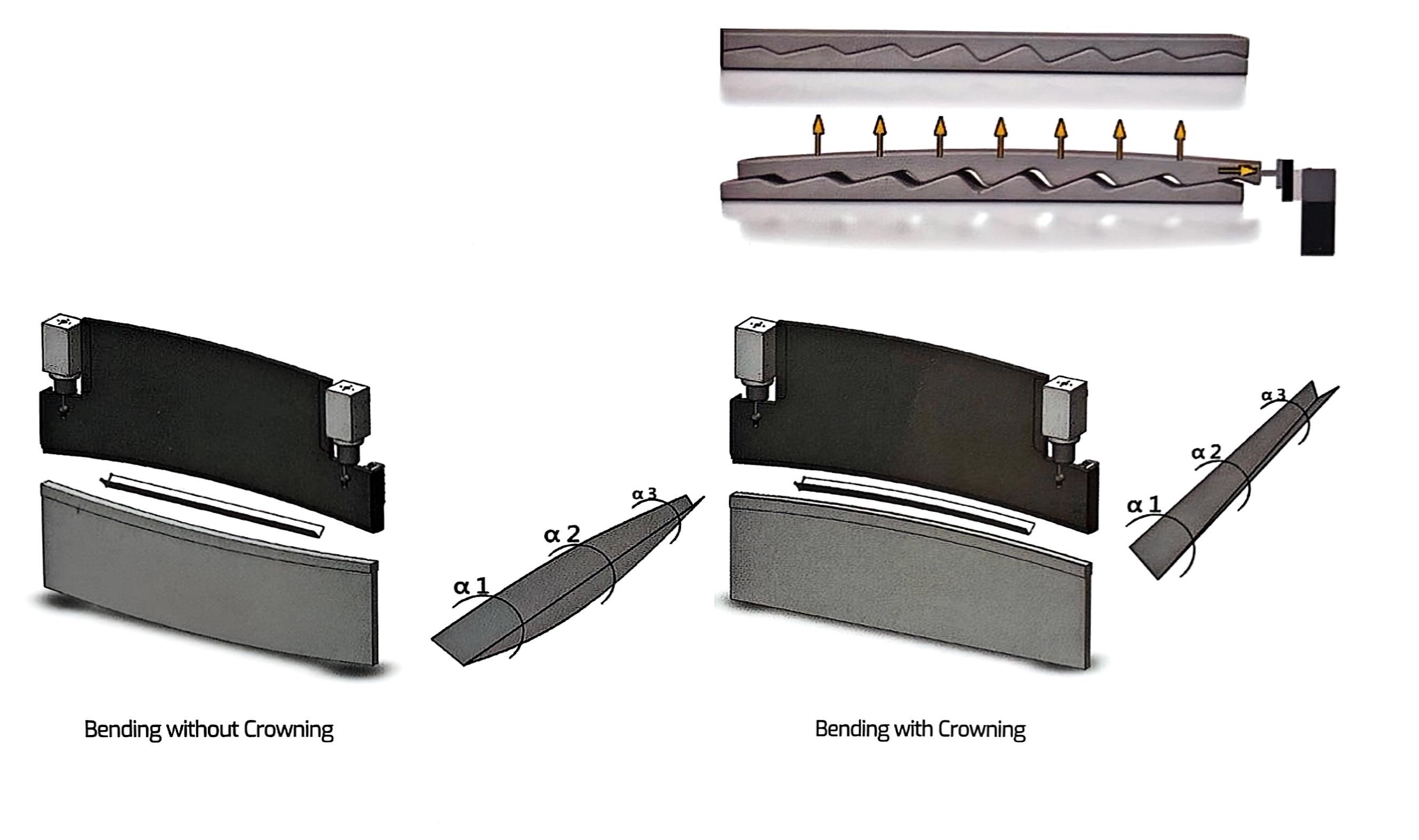

Mechanical Crowning

The compensation amount is automatically calculated and set by the NC system to ensure the consistency of the full-length bending angle.

Mechanical Compensation Crowning System

The compensation closed-loop control has high control accuracy,and the compensation amount is automatically calculated and set by the NC system to ensure the

consis- tency of the full-length bending angle and straightness.

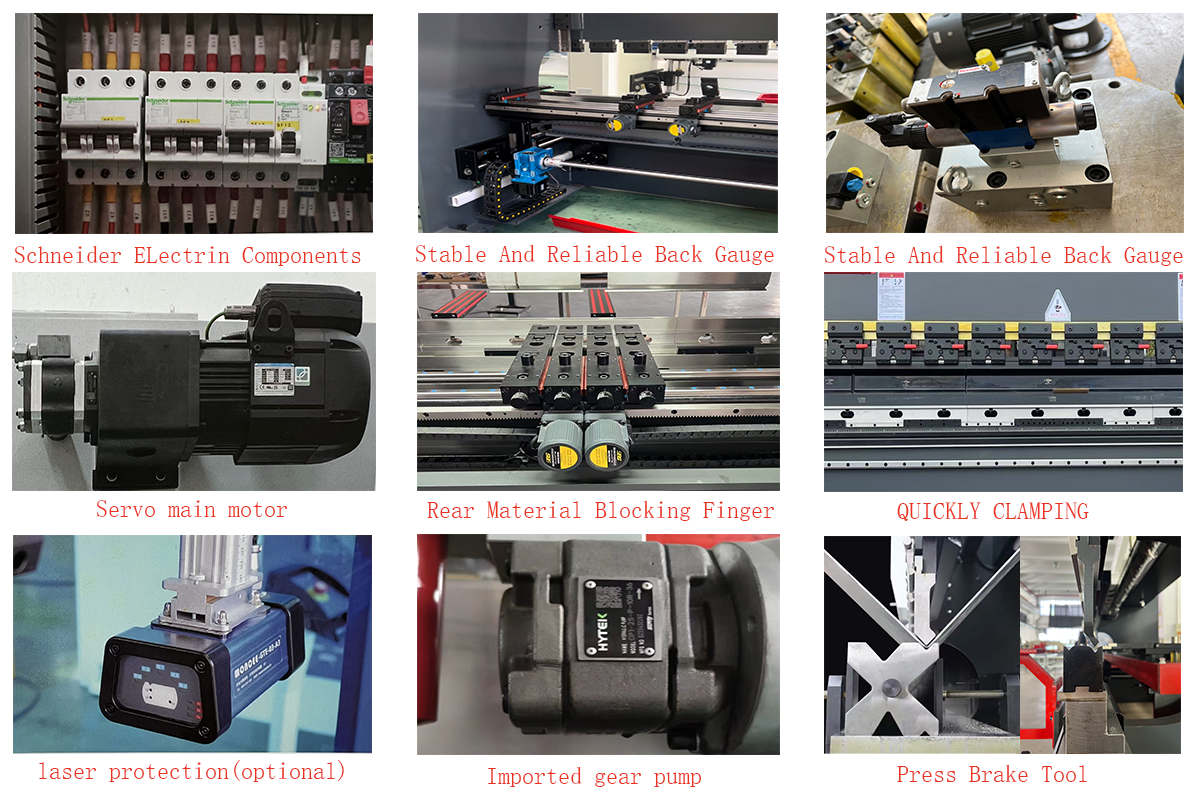

Product Details Display

Related products

-

OPTIMIZING CROSS CUT SAW MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

-

Optimizing Cross Cut Saw MAXCUT CS15/15XL

Contact UsMAX CUT CS15/15XL, as a relatively practical type of cross cut saw, it is designed for the bending timber, such as rubber wood.

-

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export.

Reviews

There are no reviews yet.